Your Phone is a Geopolitical Weapon: A Chip War Review

How semiconductor manufacturing became the most dangerous chokepoint in global technology and why Taiwan holds the world hostage

TL;DR: Semiconductors power everything from your iPhone to fighter jets. Right now, 90% of the world’s advanced chips come from a single island that China has promised to invade. Chris Miller’s “Chip War” unpacks how we got here and why this dependency might be civilization’s most fragile single point of failure.

TSMC makes the entire digital world possible. And it sits 100 miles from mainland China.

Why Does Every Tech Giant Suddenly Care About Semiconductor Manufacturing?

You probably think chips are just components. Little rectangles of silicon that go inside phones and laptops.

Wrong.

Chips are the new oil. Chris Miller’s “Chip War” lays this out in uncomfortable detail: semiconductors have become the most strategically important product on Earth, and we’ve built a global economy on top of a supply chain that’s absurdly fragile.

Intel is spending $20 billion on Arizona fabs. Samsung dropped $25 billion on a Texas facility. TSMC is pouring $165 billion into global expansion. These are national security bunkers, not business investments.

A modern leading-edge fab costs $15 to $20 billion to build. A single ASML EUV lithography machine costs $340 million and weighs 180 tons. Only five companies in the world can afford to buy them. The entry fee for this technological arms race exceeds most countries’ GDP.

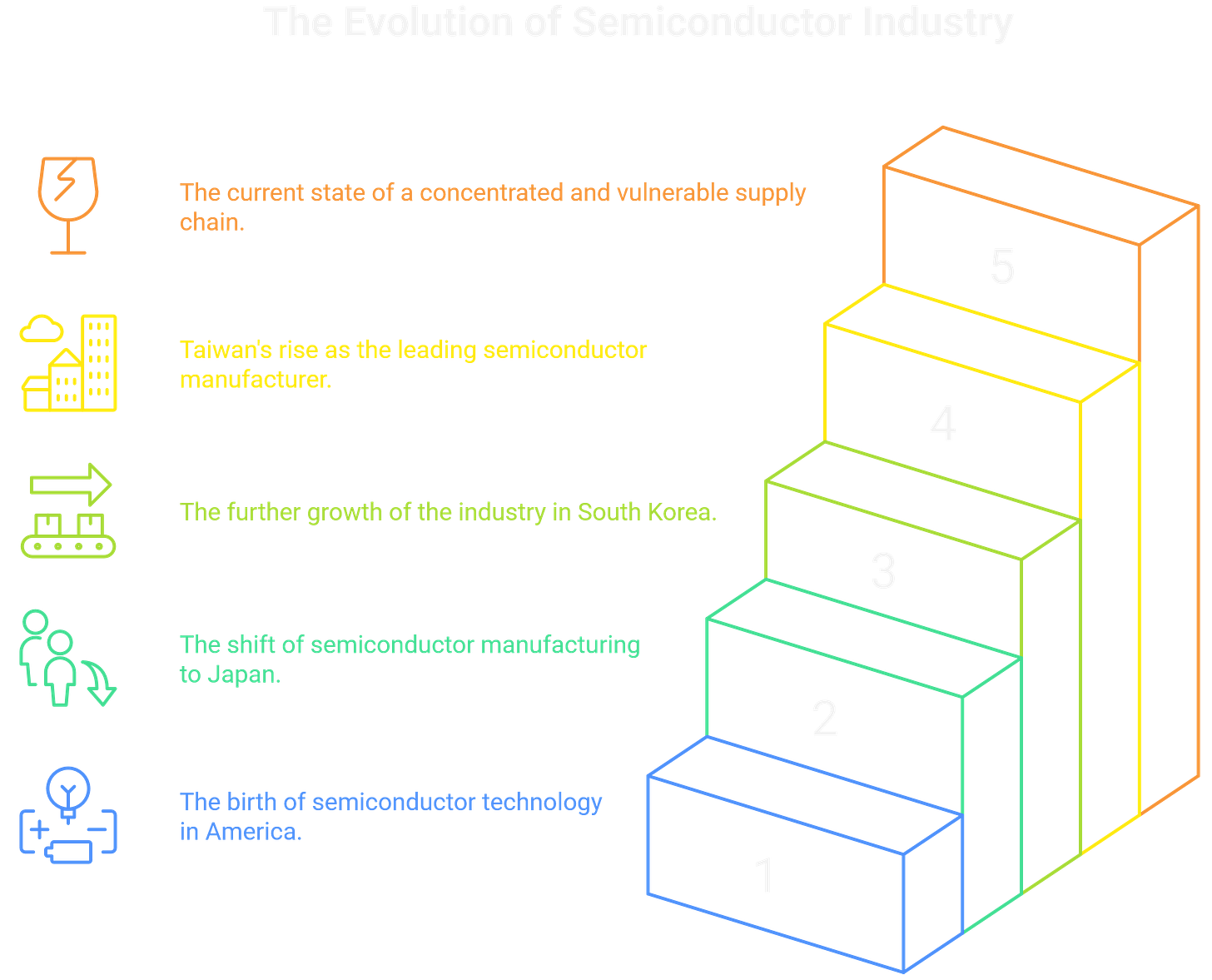

Miller traces how we got here, from the transistor’s invention through migrations to Japan, South Korea, and Taiwan. Every step made economic sense. Every step made us more fragile.

Share this analysis. Your network needs to understand why chip manufacturing just became everyone’s problem.

How Did We Go From “Transistor Radio” to “One Company Controls Everything”?

Here’s where it gets wild.

Taiwan Semiconductor Manufacturing Company produces 90% of the world’s most advanced chips. Not Taiwan’s chips. The world’s chips. Apple’s processors, Nvidia’s GPUs, AMD’s tech... all TSMC.

And TSMC depends on ASML, a Dutch company with a 100% monopoly on extreme ultraviolet lithography. Want to make chips smaller than 7 nanometers? You need ASML. No alternatives exist.

These machines are engineering marvels. ASML’s EUV systems blast tin droplets 50,000 times per second with lasers, creating plasma hotter than the sun’s surface. That plasma generates ultraviolet light bounced through mirrors polished to atomic smoothness, etching patterns 1/10,000th the width of a human hair onto silicon.

Nobody else can do this. ASML spent 20 years and $10 billion developing this, partnering with 5,000+ suppliers across 60 countries. The result requires multiple cargo planes to deliver and months to assemble.

Miller documents how this concentration happened through decades of optimization. Companies specialized. Supply chains streamlined. Costs dropped. And suddenly the digital economy depends on a handful of facilities in a contested zone.

Get the next teardown. Subscribe for more investigations into the infrastructure nobody talks about until it breaks.

What Happens When the Silicon Shield Becomes a Silicon Target?

There’s a theory called the “Silicon Shield.” It says China won’t invade Taiwan because destroying TSMC would crash the global economy, including China’s. Mutually Assured Economic Destruction.

Miller is skeptical. So are the strategists.

China doesn’t need to invade. A blockade works fine. Taiwan imports 98% of its energy and depends on constant shipments of chemicals, raw materials, and natural gas. Cut those off, and TSMC goes dark in weeks.

Recent Taiwanese research confirms this. Stockpiling won’t work. Diversifying suppliers won’t work fast enough. A selective quarantine collapses the semiconductor supply chain before any military action.

Intelligence reports point to 2027 as a key timeline for Chinese military readiness. One analyst estimated military conflict could crater TSMC’s stock by 60%. But stock prices are the minor problem.

If TSMC shuts down, we get a technological dark age. No new phones. No new cars. No new AI hardware. No new military systems. Every advanced weapon, every communications system, every data center depends on chips we can’t make anywhere else.

Join the discussion. What happens to your industry if TSMC goes offline tomorrow? Let’s talk about it in the comments.

Can We Actually Diversify Away From This Single Point of Failure?

The CHIPS Act threw $52 billion at domestic production. Europe is doing similar things. Everyone wants resilience.

Reality check: building a U.S. fab takes twice as long and costs twice as much as Taiwan. You need 30-40 million workhours, 83,000 tons of steel, and years of regulatory approvals before machines turn on.

Then you need talent. TSMC delayed its Arizona fab because they couldn’t find qualified workers. They flew in Taiwanese technicians to train Americans. Not scalable.

Miller doesn’t offer easy answers because there aren’t any. The best proposals involve multilateral cooperation: Chip 4, QUAD alliances, strategic coordination between the U.S., Japan, South Korea, and Taiwan to create redundancy without complete duplication.

It’s a triad strategy: diversify production where possible, build partnerships to share risk, accept that some dependency is unavoidable. TSMC’s decades of expertise can’t be replicated with subsidies.

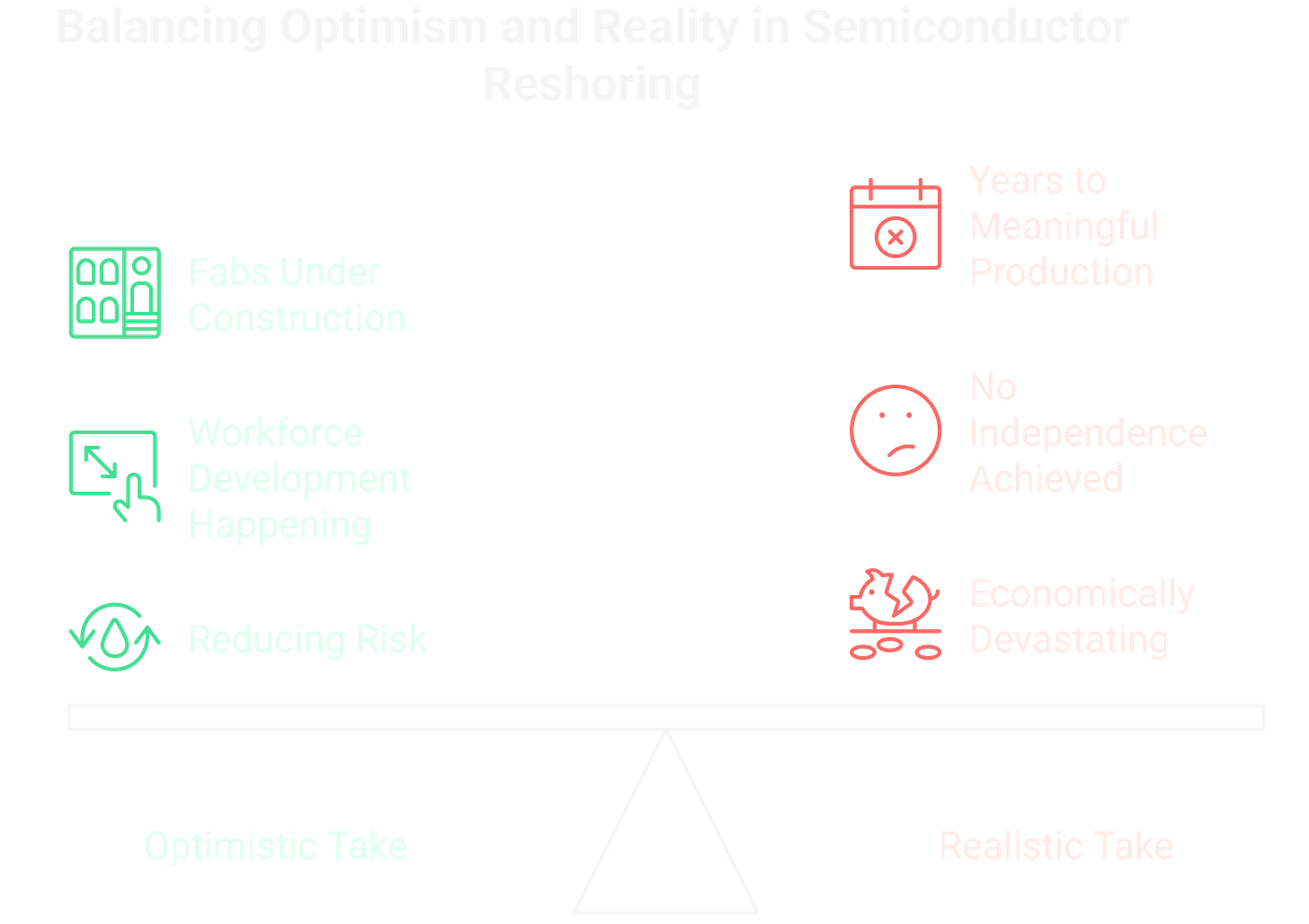

The optimistic take? We’re taking this seriously. Fabs are under construction. Workforce development is happening.

The realistic take? We’re years from meaningful production, and even then we won’t achieve independence. Best case is reducing risk from “civilization-ending” to “economically devastating.”

The world runs on chips made in one place, using machines made in another. If either has a bad decade, everyone does.

Are you working on these fab projects? Drop your insights below on what’s really happening on the ground.

Special Thanks:

- For the consistent fun engagement. - For the great and actionable content.Frequently Asked Questions

Q1: Why is TSMC so important to the semiconductor industry? A: TSMC manufactures approximately 90% of the world’s most advanced chips for Apple, Nvidia, AMD, and others. As a pure-play foundry, it manufactures designs with unmatched precision and scale. No other company matches its cutting-edge technology (3nm, 2nm processes), capacity, and decades of expertise.

Q2: What is an EUV lithography machine and why does it matter? A: EUV machines are the only tools capable of manufacturing advanced chips below 7 nanometers. They create plasma hotter than the sun to generate ultraviolet light, precisely directed through atomic-level mirrors to etch microscopic patterns. ASML holds a 100% monopoly on these $340 million machines. Without EUV, modern AI chips and advanced computing would be impossible.

Q3: Can the United States become self-sufficient in semiconductor manufacturing? A: Not realistically in the near term. The CHIPS Act is building capacity, but true self-sufficiency requires decades of Taiwanese expertise, supply chains spanning 60+ countries, and a skilled workforce that doesn’t exist at scale. Building an advanced U.S. fab takes twice as long and costs twice as much as Taiwan. The achievable goal is reducing catastrophic dependence.

Q4: What is ToxSec? A: ToxSec is a cybersecurity and AI security publication that breaks down real-world threats, breaches, and emerging risks in plain language for builders, defenders, and decision-makers. It covers AI security, cloud security, threat modeling, and automation with a practical, no-fluff approach grounded in real attacker behavior.

Probably my last book review of the year, but a solid one. Chip Wars seems really relevant right now in the midst of the AI Boom. (or burst?)

Another great post, thanks for breaking this down and adding yet another book to my reading list! Do you think in 5 year's time we'll be in e same situation, or is the massive investment by American BigTech pointing to a (very late) lesson being learnt?